Action figures – Path to manufacture

In the last post we took a look at the prototyping process for an action figure.

Once a figure is designed and a prototype is produced, that’s the majority of what’s required from the design side to begin the journey of bringing it to manufacture and ultimately onwards to market. Nonetheless it’s a detailed process and having continued input from the design side can help maintain the fidelity of the customer’s vision.

We had a look through our hundreds of previous projects of all types of figures and toys to illustrate a summary of the stages involved in the process.

Forecasting

Agreeing volumes, schedules and price-points with the retail partner will be necessary to predict what can be achieved when it comes to production. There’ll be numerous decision points along the way both small and large, and every opportunity to add a feature to increase the appeal of the product will accordingly add time and cost. Knowing the priorities will get the best value for money.

Packaging design

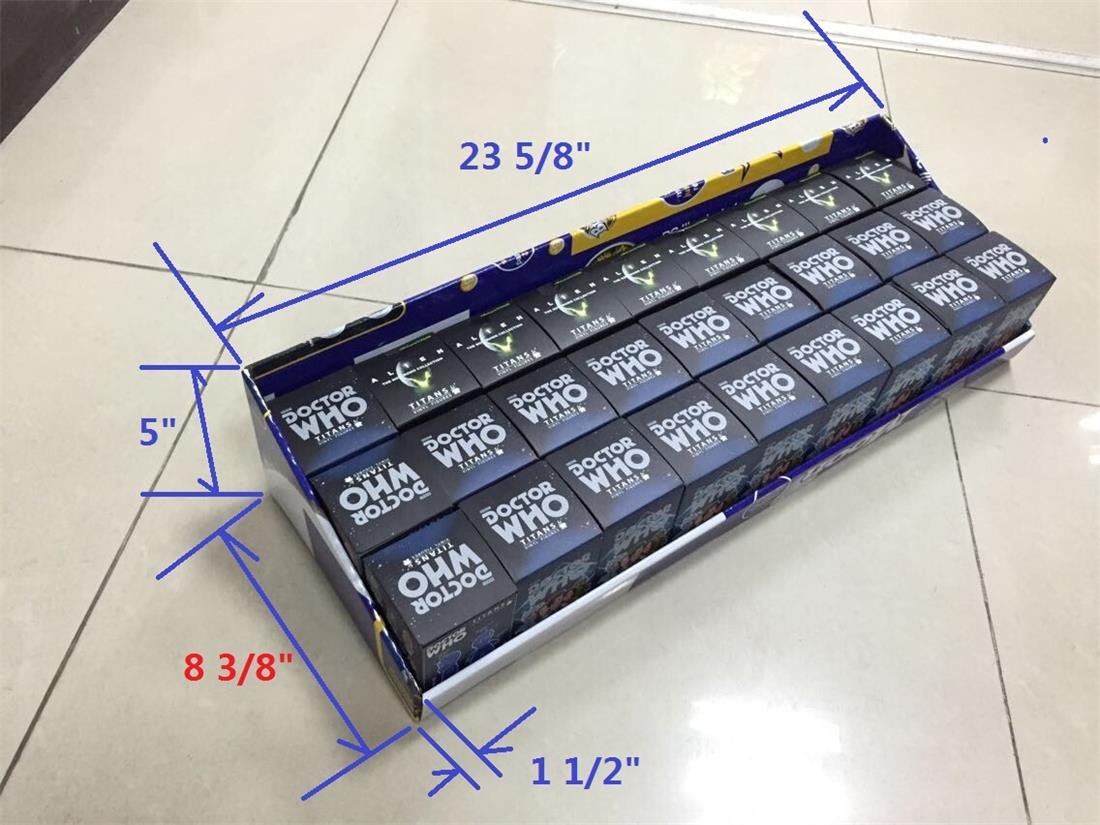

The packaging will constitute part of the overall budget and likely be where the product goes immediately as it comes off the assembly line. It may simply be a protective environment for shipping via e-commerce, or it may also need to give the ‘big sell’ on-shelf alongside competing products. Knowing what it looks like, how it functions, and the information it’s communicating now will be necessary during the next stage, procurement.

Procurement

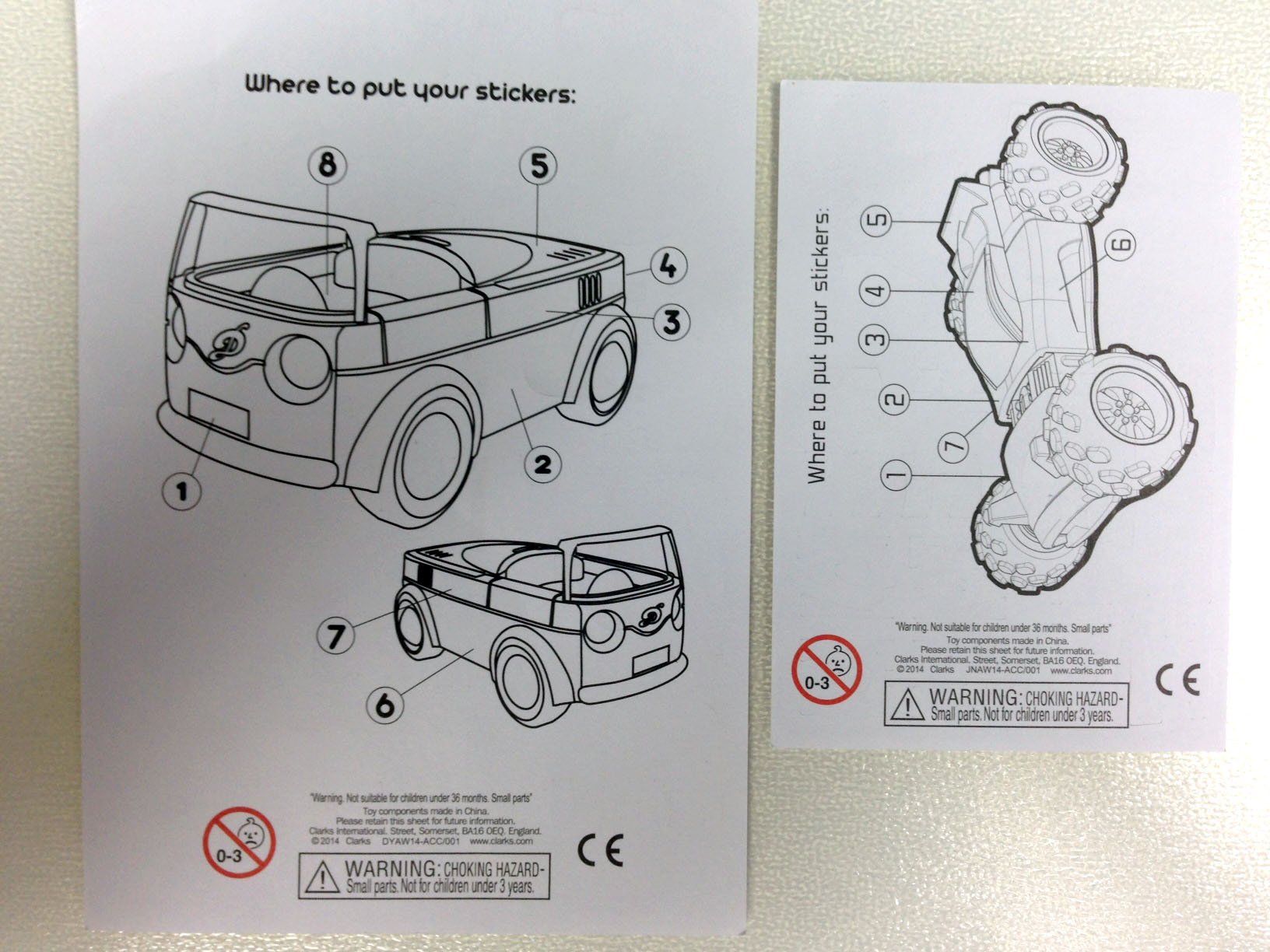

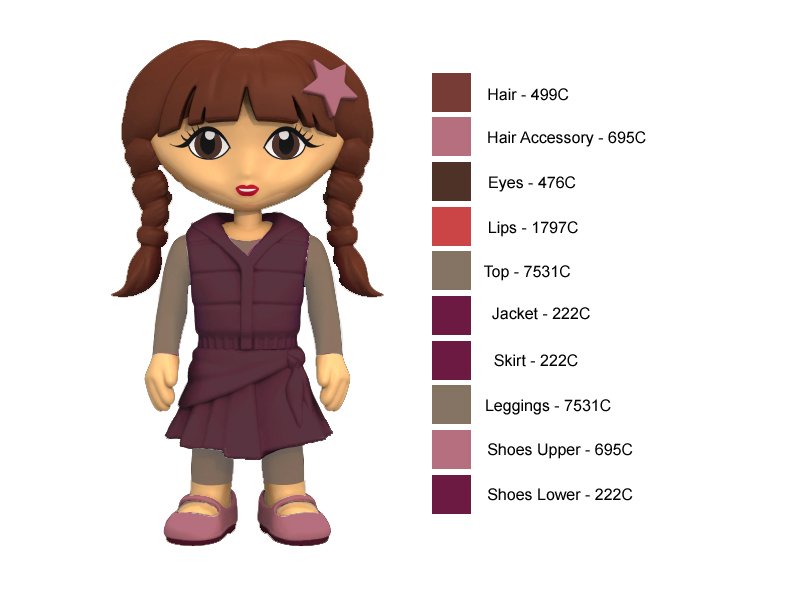

For a complex product like an action figure, costumers will often engage a vendor with an existing supplier network who can facilitate all the various processes they need for a finished and packaged product. Reference systems exist to define things like colour, texture, paper/card weight and so on. Preferences for these details will be captured in PMS documentation (Progress Measurement Sheet) which may need to be understood across multiple languages. This documentation along with the forecast volumes and schedule will feed into the next stage, quotation.

Quotations and contracts

Naturally, quotations will be something customers will want to get multiples of. The vendors will be able to provide broken-down quotes to help shape the evolving PMS to get the product in on budget.

There are set-up costs in the next stage that the vendor will need prior to starting design for manufacture, as well as commitment to the anticipated volumes.

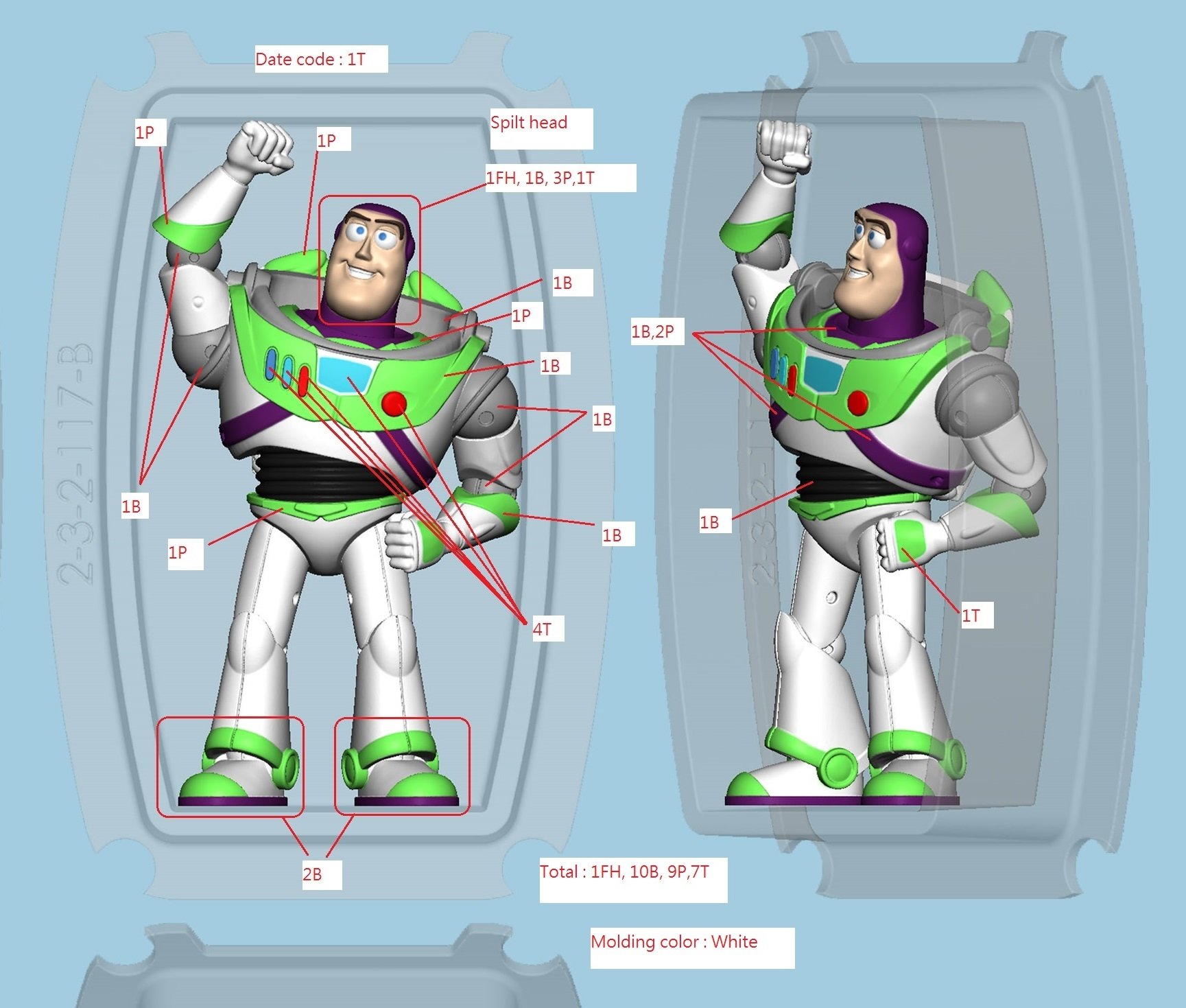

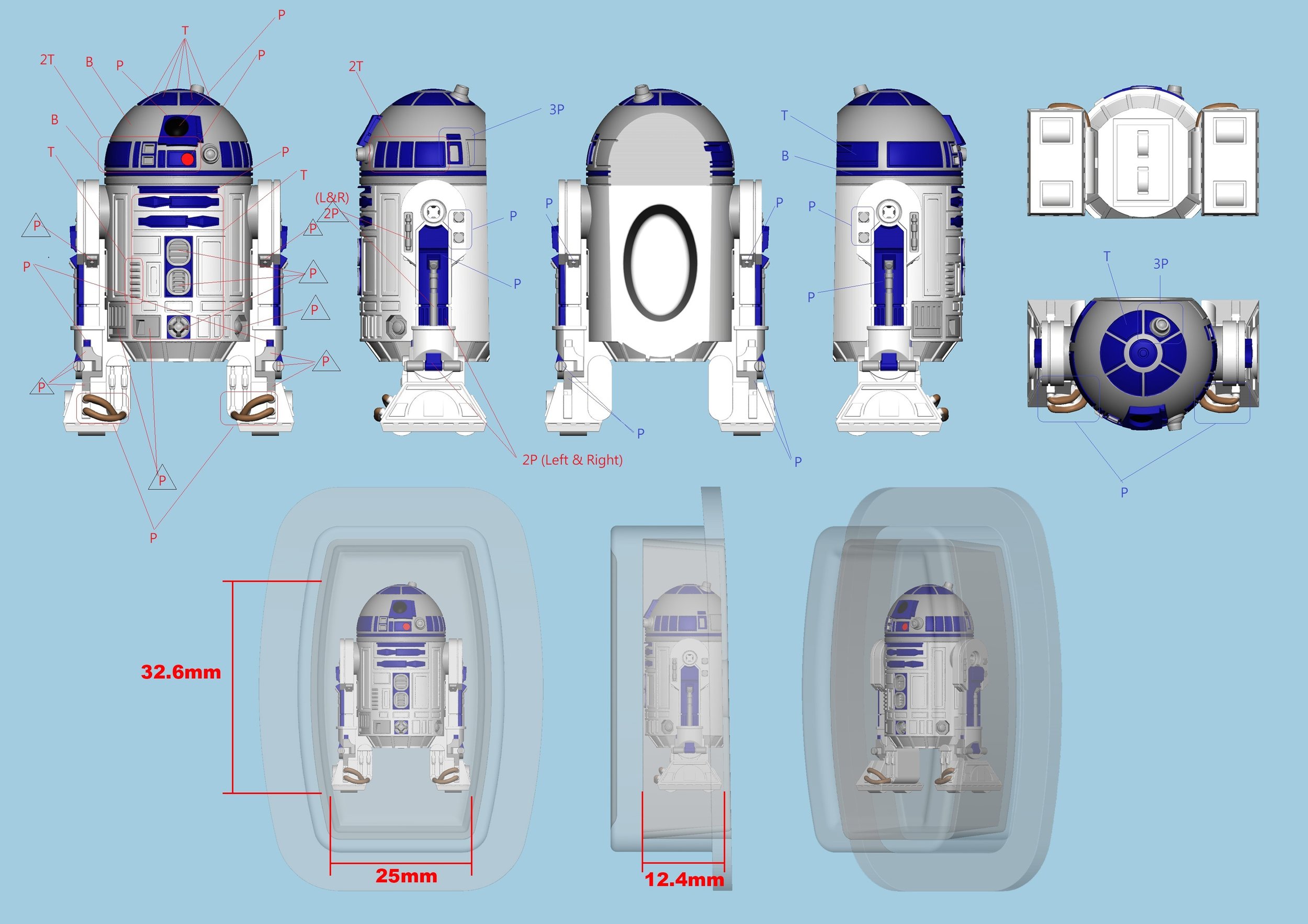

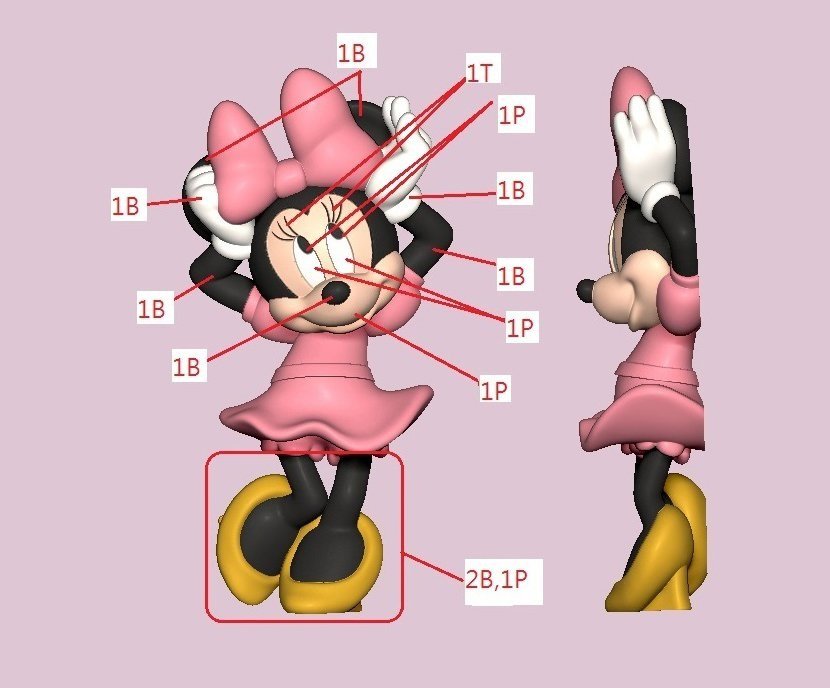

Tool design

Depending on the processes and suppliers the selected vendor uses, they will need to translate the design to information that can be used for manufacture. This will be the design of mould tools and jigs that will be used in production. The nature of them will be driven by the design and by the anticipated volumes. There will likely be some further adjustment to the PMS here as the design is optimised for cost and efficiency of production.

Sampling / T0 / FOT

After the tools are designed and made, a first-off rough version of the product will be produced. It won’t have fully representative colours, materials and processes, but will provide an indication where slight changes can be made to further optimise the design. It will also help initiate the next stage, compliance.

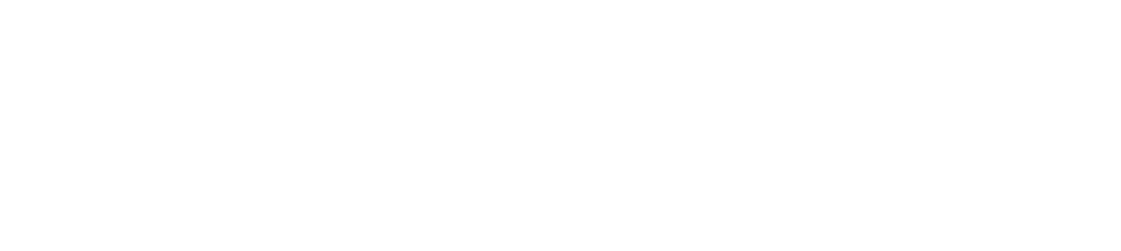

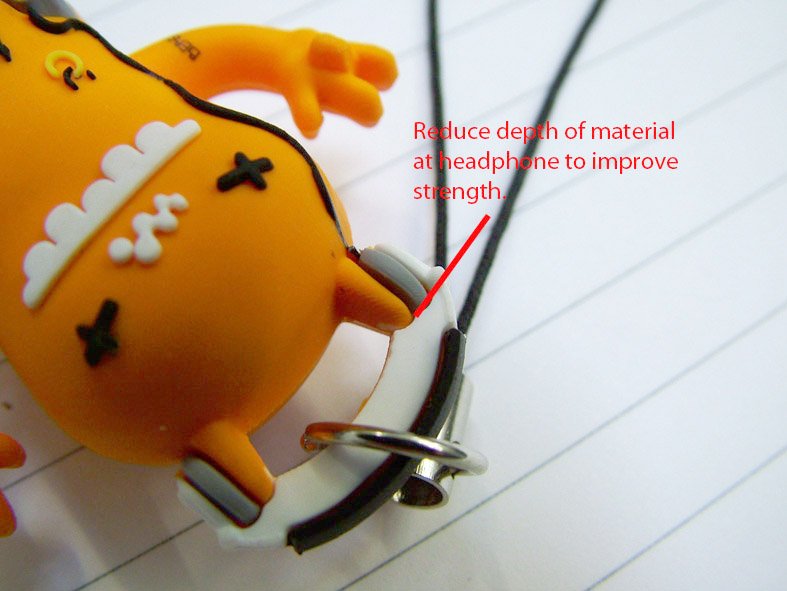

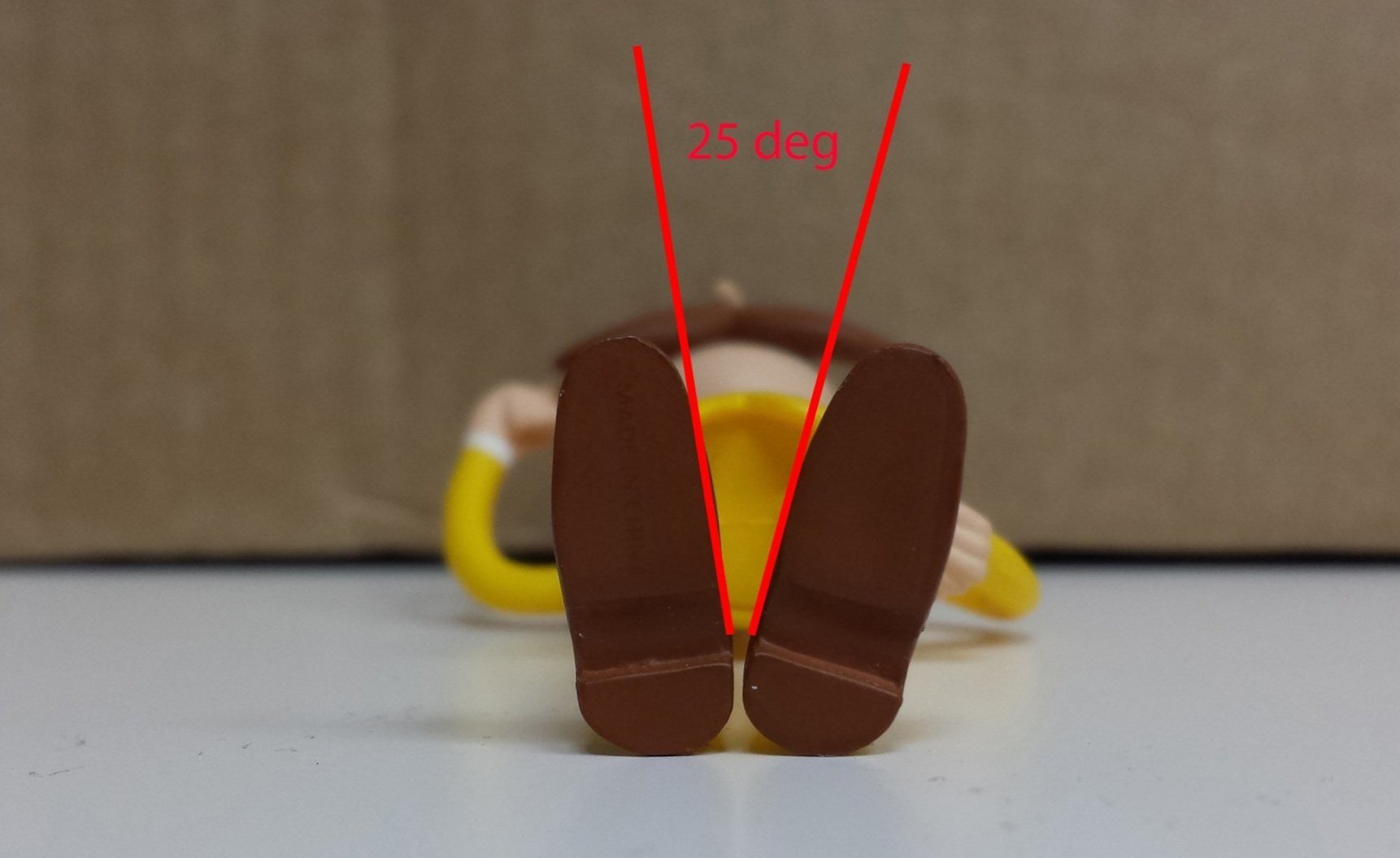

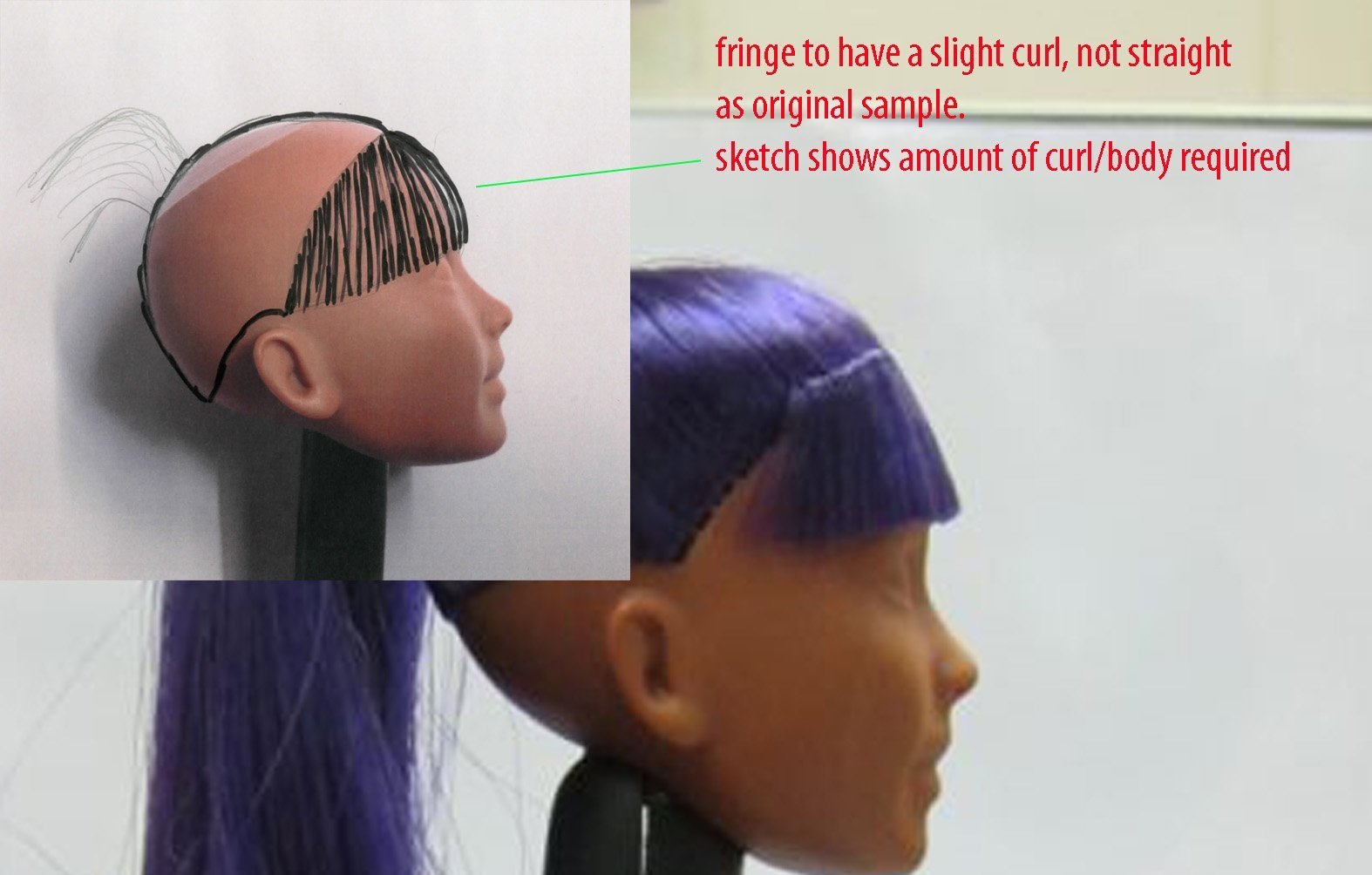

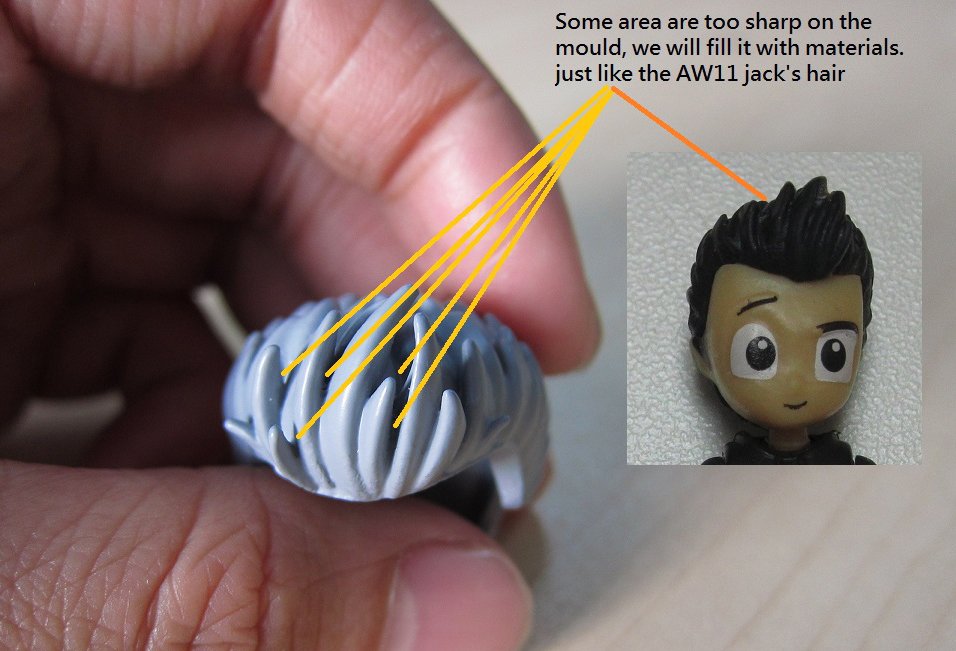

T0 Samples

Sample feedback

Compliance

Depending on the age of consumer the product is for it may need to submit to compliance testing for safety. This is different for different ages and in different territories. The sample should provide sufficiently representative materials and assembly that it will be indicative of the performance of the actual finished article. This compliance testing is a one-off cost and will form part of the budget for the overall development.

Golden sample

Now that the design is optimised, agreed and has passed compliance, it’s ready for production. The mould tools will be finished and polished, extra parallel tool sets may be produced, and the necessary materials will be ordered to make the product in volume.

The golden sample acts as a first-off fully representative instance of the product and will be signed-off by the customer. The suppliers and vendors will have QA (Quality Assurance) personnel on site to monitor production, and this sample will form the benchmark for them throughout the production. This will maintain the quality standard is met for all the details specified in the PMS documentation.

Production

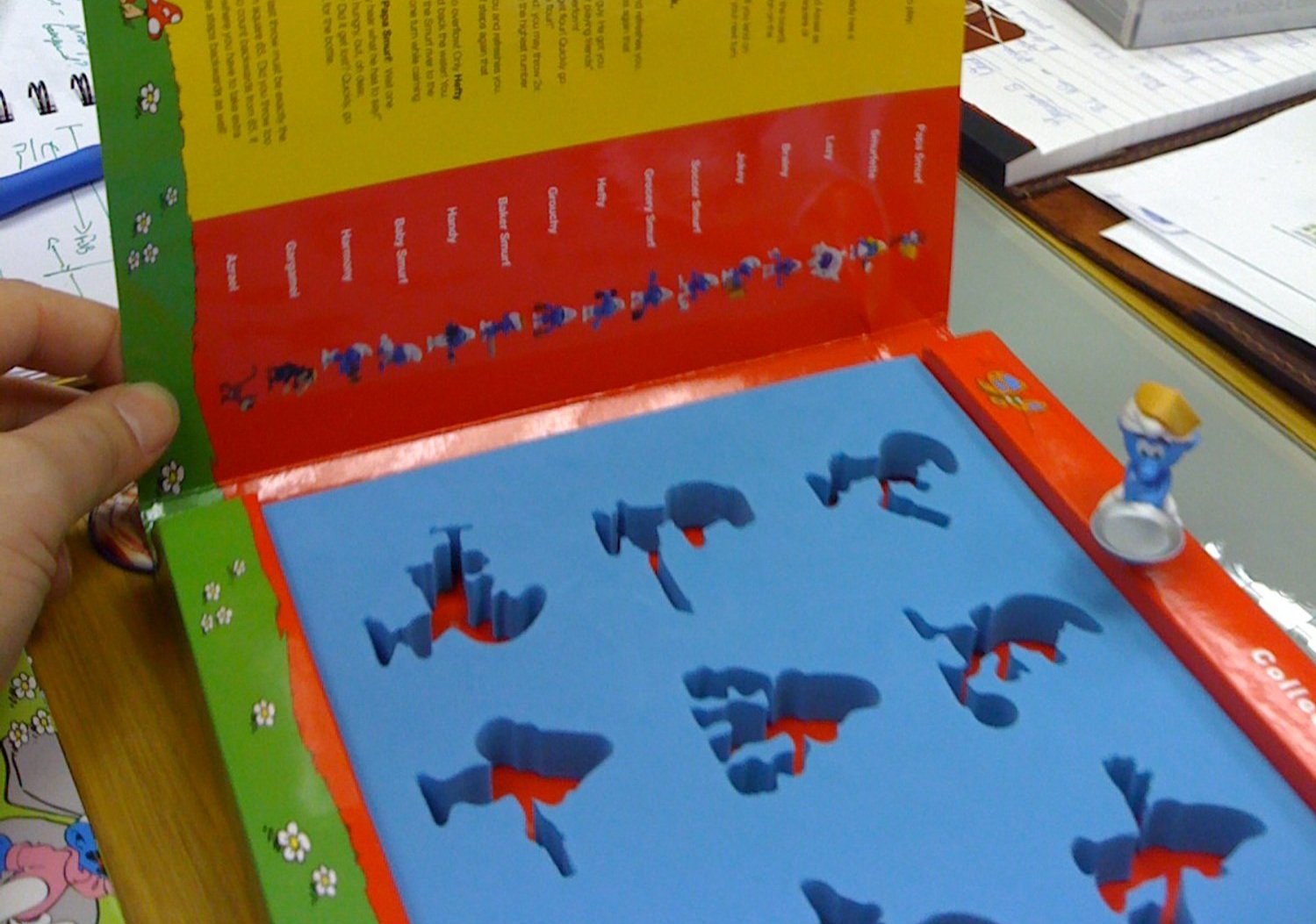

Unless the volumes are very high, this can be rather quick. Many suppliers work a six day week and may run shifts around the clock. The output will be the packaged product in its retail packaging, packed again for the next stage, freight.

Decoration process

Assembly process

Freight

How the product ships will depend on where it’s going and if it’s by air or sea. Ideally the primary packaging will have been designed to consider this and be designed for efficient freight packaging and palletisation.

Freight can take a surprisingly long time. Sea freight from the Far East to Europe for example is over 40 days.

Distribution and Retail

Once the product makes landfall in it’s destination country and relevant declarations, duties and taxes are settled it passes to distribution for storage and ultimately retail. Even at this final stage, the volumes mapped-out during forecasting will help to ensure there is always enough inventory available but minimise the amount that is held in storage.

If you’ve a an action figure or toy design that requires experienced support bringing to market, why not reach out below.